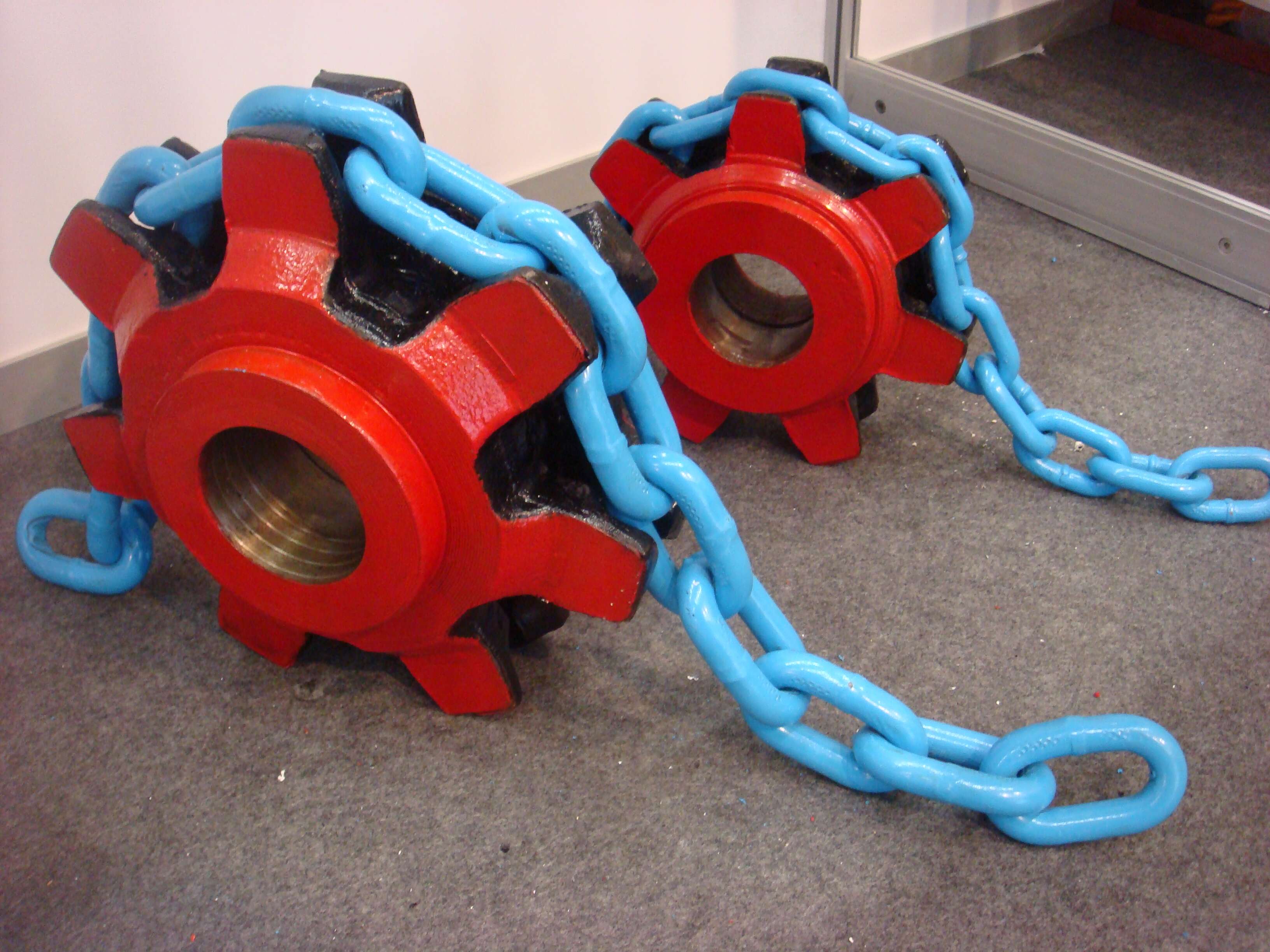

Is a kind of button with embedded tooth chain sprocket gear wheels, with section to link or cable pitch accurate block mesh. Sprocket is widely used in chemical industry, textile machinery, escalators, wood processing, parking equipment, agricultural machinery, food processing, instrument, such as oil industry of mechanical transmission, etc.

Sprocket tooth profile

Chain sprocket tooth profile must ensure that the energy saving mesh smooth entry and exit freely, minimize the impact of the meshing of link and contact stress, and is easy to be processed. Commonly used sprocket end tooth shape as shown in figure 1. It consists of three sections of circular arc aa, ab, CDS and a straight line BC, referred to as "three arc - straight tooth. Sprocket tooth profile using a standard cutting tool processing, work in don't have to draw end tooth shape on the graph, only need to indicate on the diagram "tooth profile according to provisions of 3 rgb1244-85", but should draw the axial plane of sprocket tooth, its dimensions refer to the design manual.

Sprocket structure

Four kinds of common structure of sprocket. Small diameter sprocket made of monolithic, medium diameter of sprocket to make radial plate more, for ease of handling, loading and weight loss, on the radial plate hole, large diameter combined sprocket can make it, at this moment, in different material ring gear and the wheel core is available. The C45, for example, the material such as stainless steel.

Sprocket material

Sprocket should guarantee the tooth have enough strength and abrasion resistance, so the sprocket tooth surface is generally after heat treatment, to a certain hardness.

Sprocket tooth profile

Chain sprocket tooth profile must ensure that the energy saving mesh smooth entry and exit freely, minimize the impact of the meshing of link and contact stress, and is easy to be processed. Commonly used sprocket end tooth shape as shown in figure 1. It consists of three sections of circular arc aa, ab, CDS and a straight line BC, referred to as "three arc - straight tooth. Sprocket tooth profile using a standard cutting tool processing, work in don't have to draw end tooth shape on the graph, only need to indicate on the diagram "tooth profile according to provisions of 3 rgb1244-85", but should draw the axial plane of sprocket tooth, its dimensions refer to the design manual.

Sprocket structure

Four kinds of common structure of sprocket. Small diameter sprocket made of monolithic, medium diameter of sprocket to make radial plate more, for ease of handling, loading and weight loss, on the radial plate hole, large diameter combined sprocket can make it, at this moment, in different material ring gear and the wheel core is available. The C45, for example, the material such as stainless steel.

Sprocket material

Sprocket should guarantee the tooth have enough strength and abrasion resistance, so the sprocket tooth surface is generally after heat treatment, to a certain hardness.

- 2019-12-24The chain quality development work

- 2019-12-24High intensity ring chain making process

- 2019-12-24Lifting chain in the installation should pay attention to what

- 2019-12-24Advanced Mine Equipment Factory teach you how to choose the chain lock

- 2019-12-24Chain installation is correct or not directly affect the chain driving quality and service life of the chain

- 2019-12-24Elevator chain frequency conversion technology to complete the high efficiency mode

- 2019-12-24The development of chain industry in China sustained growth

- 2019-12-24Failure to wear fault chain conveyor chain

Mine high strength round link chain

Mining high strength compact chain

Machine in dregs carburizing wear-resisting chain

High strength lifting chain

High strength lifting sling

Stainless steel chain sprocket series

Chain bucket lift machine

High intensity mining sprocket, customized sprocket

All kinds of gb, din, and other standard chain can be customized

Mining scraper

Contact us

Tel:0538-7460888 7460999

Fax:0538-7460088

Website:www.sdxjlt.com

Sales manager:xianjin JI

Phone:13953829898

WeChat:18853899608

QQ:1023734886

Email:sdxjks@163.com

Address:Officer in xintai city in shandong province sheep flow industrial west bridge