Requirements for ring chain

(1) Under the same material and section, it should have higher bearing capacity;

(2) have larger breaking load and elongation;

(3) have smaller deformation under the effect of bearing capacity to ensure good engagement;

(4) have higher fatigue strength;

(5) have higher wear resistance;

(6) have higher toughness and absorb impact load Capacity;

(7) the geometric dimension shall meet the drawing requirements.

matters needing attention:

1. This kind of fracture mostly occurs in the defective parts of the shoulder or straight arm of the chain link, such as the crack welding heat affected zone and the crack of individual bar

2. Before the chain reaches the breaking load, it will produce the fracture caused by fatigue, which mostly occurs at the joint of straight arm and circular arc of the chain link

- 2019-12-24Failure to wear fault chain conveyor chain

- 2019-12-24Precautions for maintenance and repair of serrated

- 2019-12-24Chain selection and use should pay attention to what

- 2019-12-24Chain type using the chain drive rich

- 2019-12-24The chain quality development work

- 2019-12-24Mining and the use of compact chain operation meth

- 2019-12-24Stainless steel chain is suitable for a variety of

- 2019-12-24High intensity ring chain making process

Mine high strength round link chain

Mining high strength compact chain

Machine in dregs carburizing wear-resisting chain

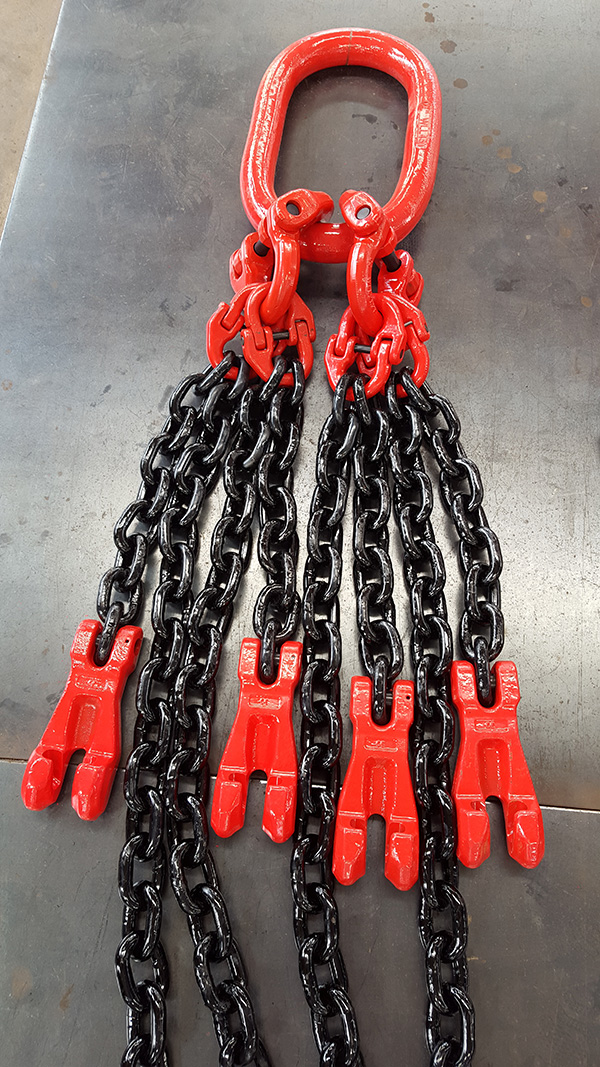

High strength lifting chain

High strength lifting sling

Stainless steel chain sprocket series

Chain bucket lift machine

High intensity mining sprocket, customized sprocket

All kinds of gb, din, and other standard chain can be customized

Mining scraper

Contact us

Tel:0538-7460888 7460999

Fax:0538-7460088

Website:www.sdxjlt.com

Sales manager:xianjin JI

Phone:13953829898

WeChat:18853899608

QQ:1023734886

Email:sdxjks@163.com

Address:Officer in xintai city in shandong province sheep flow industrial west bridge