1. Basic requirements for gear accuracy

It has been proved by practice that the gear accuracy must be controlled at gb10995-887 ~ 8 level, the linear speed is higher than 20 m / s gear, and the tooth pitch limit deviation, ring gear radial runout tolerance and tooth direction tolerance must be stable to reach 7 level accuracy. In the case of Grade 7 precision gear, the shuttle should be reversed at the tooth part and the root boss should be strictly prevented.

2. Control the quality of raw materials

High quality raw materials are the prerequisite for the production of high-quality products. No matter which way is adopted, the raw materials must go through strict chemical composition inspection, grain size measurement and purity assessment after arriving at the factory. Its purpose is to adjust the deformation of heat treatment in time and improve the quality of tooth profile processing.

3. Prevent heat treatment deformation

After rough machining, the gear blank is made into precision forging and normalized or tempered to achieve: (1) soften the steel parts for machining; (2) eliminate residual stress; (3) refine the grains and improve the structure to improve the mechanical properties of the steel; (4) make organizational preparation for the treatment. It should be noted that in the normalizing or tempering treatment, it is necessary to keep the furnace temperature uniform, and use the working position apparatus to make the workpiece evenly heated and cooled. It is strictly prohibited to stack them together. Ensure the accuracy of the gear blank according to the design requirements. . gear cutting processing measures: the purchased gear cutting tools must be inspected and meet the requirements of Class AA. After the grinding of gear cutting tool, it is necessary to check the radial property of the front edge of the tool, the difference between adjacent circumferential joints of the chip holding groove, the large accumulated error of the circumferential joints of the chip holding groove, and the parallelism between the front of the tooth and the axis of the inner hole.

- 2019-12-24The chain quality development work

- 2019-12-24High intensity ring chain making process

- 2019-12-24Failure to wear fault chain conveyor chain

- 2019-12-24Sawtooth link material and heat treatment process

- 2019-12-24Heat Treatment of Circular Chain of Mine

- 2019-12-24Precautions for maintenance and repair of serrated

- 2019-12-24The basic components of the national standard in the chain transmission chain

- 2019-12-24Manufacturing process of Shandong Province, Xintai city of advanced mine equipment chain

Mine high strength round link chain

Mining high strength compact chain

Machine in dregs carburizing wear-resisting chain

High strength lifting chain

High strength lifting sling

Stainless steel chain sprocket series

Chain bucket lift machine

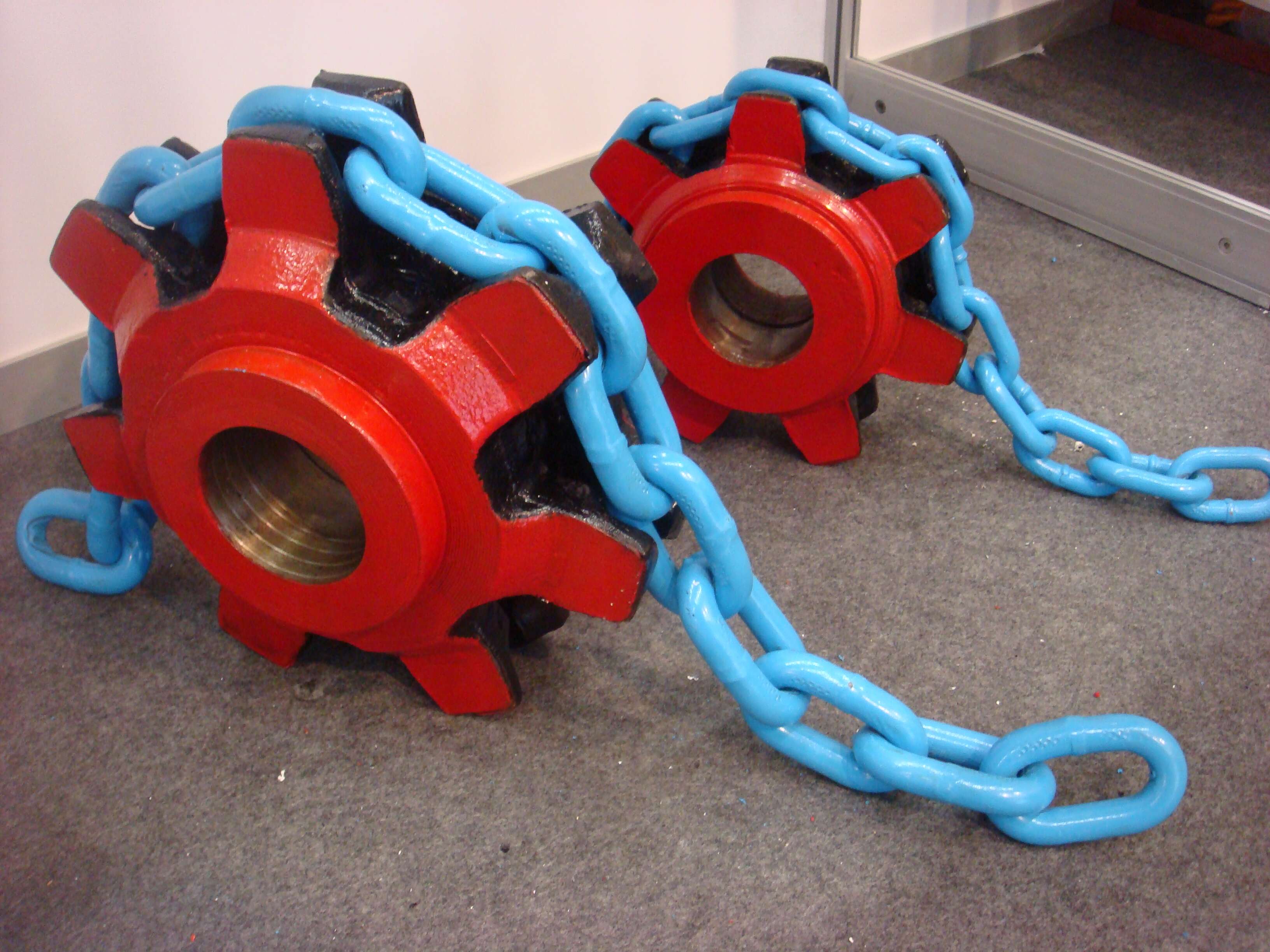

High intensity mining sprocket, customized sprocket

All kinds of gb, din, and other standard chain can be customized

Mining scraper

Contact us

Tel:0538-7460888 7460999

Fax:0538-7460088

Website:www.sdxjlt.com

Sales manager:xianjin JI

Phone:13953829898

WeChat:18853899608

QQ:1023734886

Email:sdxjks@163.com

Address:Officer in xintai city in shandong province sheep flow industrial west bridge