- 2019-12-24Lifting chain in the installation should pay attention to what

- 2019-12-24Crane chain exactly how to maintenance and maintenance

- 2019-12-24The chain quality development work

- 2019-12-24The Common Heat Treatment Method and Aging Treatment of Chain

- 2019-12-24The chain of high temperature lubricating oil

- 2019-12-24Precautions for maintenance and repair of serrated

- 2019-12-24In the development process of chain industry problems

- 2019-12-24Advanced Mine Equipment Factory teach you how to choose the chain lock

Mine high strength round link chain

Mining high strength compact chain

Machine in dregs carburizing wear-resisting chain

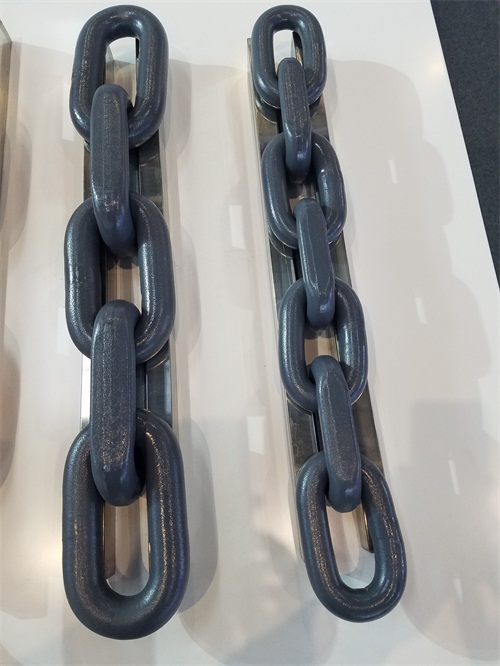

High strength lifting chain

High strength lifting sling

Stainless steel chain sprocket series

Chain bucket lift machine

High intensity mining sprocket, customized sprocket

All kinds of gb, din, and other standard chain can be customized

Mining scraper

Contact us

Tel:0538-7460888 7460999

Fax:0538-7460088

Website:www.sdxjlt.com

Sales manager:xianjin JI

Phone:13953829898

WeChat:18853899608

QQ:1023734886

Email:sdxjks@163.com

Address:Officer in xintai city in shandong province sheep flow industrial west bridge