1. The sprocket wheel shall be installed on the shaft without skew and swing. The end faces of two sprocket wheels in the same transmission component shall be in the same plane. When the center distance of the sprocket wheel is less than 0.5m, the allowable deviation is 1mm; when the center distance of the sprocket wheel is more than 0.5m, the allowable deviation is 2mm. However, it is not allowed to have friction on the side of the sprocket wheel. If the two wheels are too large, it is easy to cause chain disconnection and accelerated wear. Pay attention to check and adjust the offset when replacing the sprocket wheel.

2. The tightness of lifting chain shall be appropriate, too tight increases power consumption, and the bearing is easy to wear; too loose chain is easy to jump and fall off. The tightness of the chain is: lift or press from the middle of the chain, and the center distance between two sprocket wheels is about 2% - 3%.

3. The new lifting chain is too long or elongated after use, which is difficult to adjust. The chain link can be removed according to the situation, but it must be an even number. The chain link shall pass through the back of the chain, the locking piece shall be inserted outside, and the opening of the locking piece shall face the opposite direction of rotation.

4. After the sprocket wheel is seriously worn, replace it with a new sprocket wheel and a new chain at the same time to ensure good engagement. It is not allowed to replace the new chain or sprocket wheel alone. Otherwise, it will cause poor engagement and accelerate the wear of new chain or new sprocket wheel. When the tooth surface of sprocket wheel is worn to a certain extent, it shall be turned over for use in time (it refers to the sprocket wheel used for adjustable surface). To extend the use time.

5. The old lifting chain shall not be mixed with some new chains, otherwise it is easy to have impact in the transmission and pull the chain off.

6. During the operation of lifting chain, please remember to add lubricating oil in time. The lubricating oil must enter the fitting clearance between the roller and the inner sleeve to improve the working conditions and reduce the wear

- 2019-12-24Lifting chain in the installation should pay attention to what

- 2019-12-24Chain installation is correct or not directly affect the chain driving quality and service life of the chain

- 2019-12-24Chain type using the chain drive rich

- 2019-12-24Lifting chain in the installation should pay attention to what

- 2019-12-24The Common Heat Treatment Method and Aging Treatment of Chain

- 2019-12-24Advanced Mining MachineryChain maintenance knowledge

- 2019-12-24Sawtooth link material and heat treatment process

- 2019-12-24Failure to wear fault chain conveyor chain

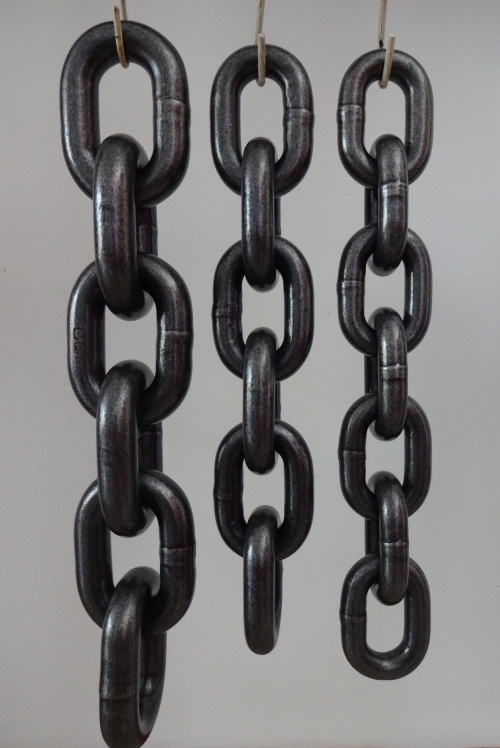

Mine high strength round link chain

Mining high strength compact chain

Machine in dregs carburizing wear-resisting chain

High strength lifting chain

High strength lifting sling

Stainless steel chain sprocket series

Chain bucket lift machine

High intensity mining sprocket, customized sprocket

All kinds of gb, din, and other standard chain can be customized

Mining scraper

Contact us

Tel:0538-7460888 7460999

Fax:0538-7460088

Website:www.sdxjlt.com

Sales manager:xianjin JI

Phone:13953829898

WeChat:18853899608

QQ:1023734886

Email:sdxjks@163.com

Address:Officer in xintai city in shandong province sheep flow industrial west bridge